Additive Manufacturing in Robotics

Introduction

Robotics and 3D printing both have the potential to hugely impact the manufacturing landscape in the coming decades. Automatization and flexible production, which are increasingly important, are both aspects of robotics and 3d printing. Therefore, it also does not come as a surprise that those two fields have lots of synergies.

3D Printed End of Arm Tooling (EOAT)

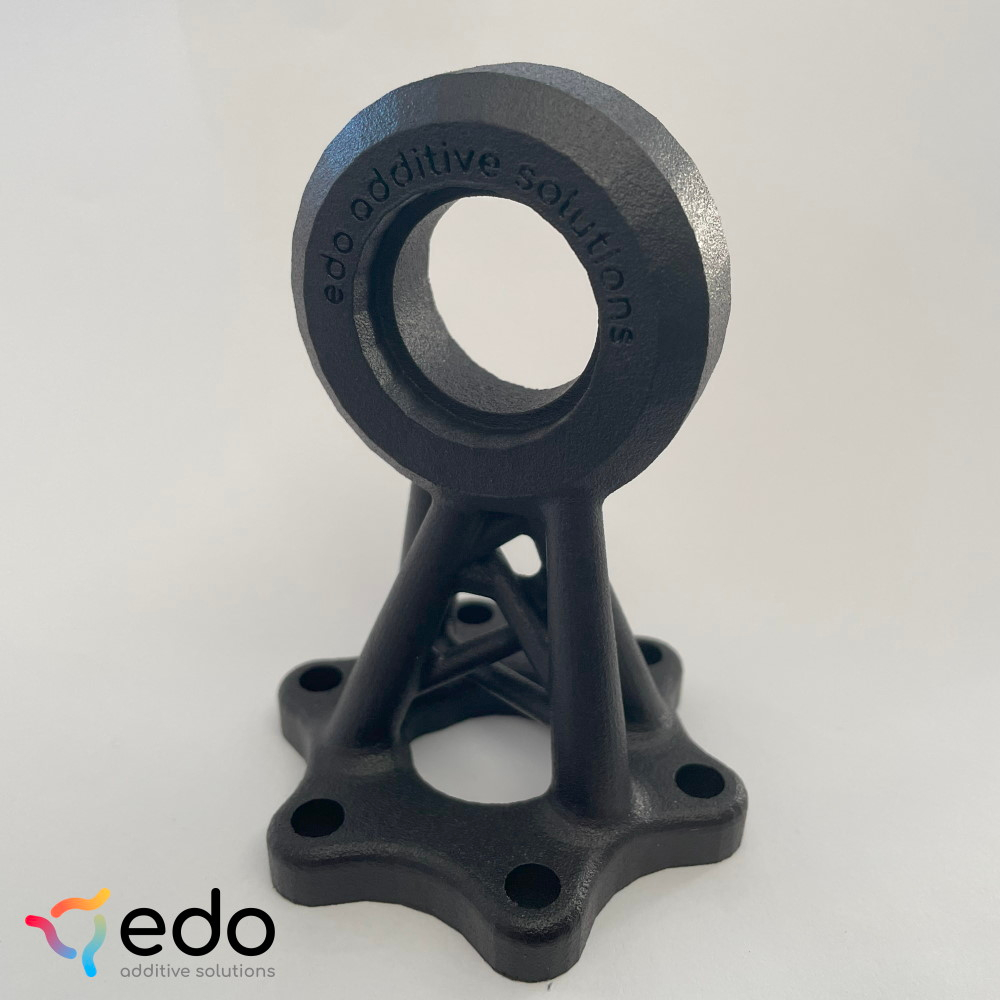

Robot arms are flexible machines used in many industries to perform a multitude of different operations. Operations include welding, unloading, and loading of other machines, part manipulation, assembly, adhesive dispensing, and many more. The issue with having many different applications is that most of them need different specific tooling (called end-of-arm tooling) for the robot to interact with the workpieces appropriately. Here, 3D printing can step in to easily create customized, low-quantity tooling. Additionally, they can be easily optimized for specific tasks, weight, forces and lead times. This combination makes robot arms, that can be produced in high quantities with economies of scale much more flexible.

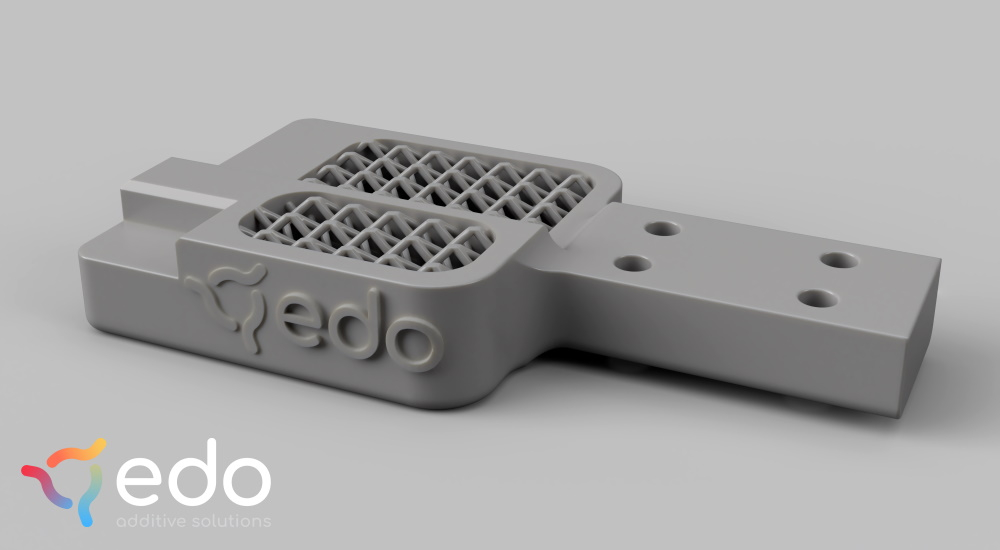

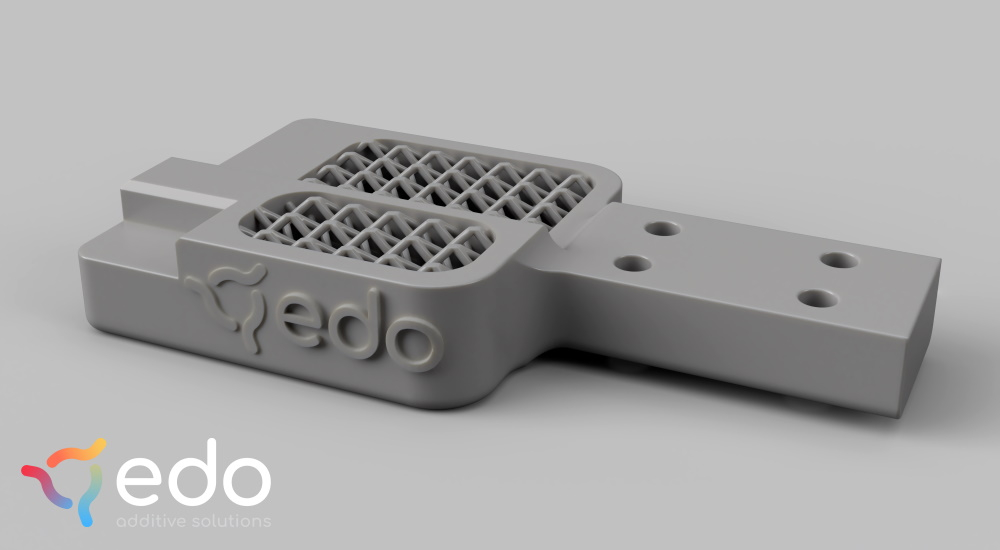

One important category of end of arm tooling are grippers, since many applications of robot arms include some sort of pick-up and place operations. For each part, there is an optimal way to grip it. Traditionally, this often involves high tooling costs to grab a part optimally. Since every part is different, this can quickly lead to high tooling costs. Therefore 3D printing is an ideal solution for these highly customized parts.

3D printed customized lightweight robot gripper

Next to the grippers, other static mounting features and holders with specialized add-ons, like integrated cooling, pneumatics, valves and so on, are areas where additive manufacturing shines as well by being able to make otherwise impossible geometries.

Repair Parts and other Accessories

When something breaks or when there is a rapid change in production needed, robots and 3d printing can play out their synergies extremely well. Because of the versatility of robots, they can be easily reprogrammed to accommodate for quick changing situations, while additive manufacturing can provide the new replacement end-of-arm tooling required in hours. This combination enables manufacturers to reduce downtimes and minimize the cost required for specialized tooling.

3D printing can also be beneficial in the immediate surroundings of robots. For example, 3D printing can provide customized parts holding for part transport outside of robot stations, create customized paneling for moving parts and help with human-robot interaction.

Soft Robotics

Soft robotics is an exciting field, the idea of moving away from rigid structures and towards more nature-like soft structures brings up new opportunities and challenges. Mimicking nature has helped technologies several times in the past. Here, it helps us to create better and softer grippers, make robots move better through difficult terrain, create more realistic prosthetics and create less damaging surgical devices and implants. However, creating those soft robots is a huge challenge with traditional manufacturing, because designs usually require internal tubing, cavities, embedded sensors, and more complex geometries. Additive manufacturing is exactly suited to produce these kinds of complex designs and therefore plays a vital role in soft robotics.

Robot-based and Robot-supported Additive Manufacturing

By now, we have talked about how additive manufacturing can enable robotics, but obviously, robotics also enables additive manufacturing. With robotic 3D printer farms, additive manufacturing can be completely automated. This greatly increases efficiency, throughput, reliability and cost. Further, there are also robots that do the 3D printing by themself, which enables the creation of usually larger parts that would be difficult to produce with traditional 3D printers.

Conclusion

Robots and 3D printing have great synergies and they can open a lot of new possibilities. If you want to discover the possibilities in your industry with us, feel free to contact us. We help you in case you need customized parts like tooling for your robots within short lead times or if you need strategic guidance and planning support for your long term additive manufacturing ideas. With our expertise, we are able to plan, design and print your needs quickly and efficiently so that your production runs as smoothly as possible.

Just give us a call or write us here.

The next releases will cover:

- Metal 3D Printing with Laser Powder Bed Fusion (LPBF)

- Weight Reductions with 3D printing

- 3D Printing of Aluminum Alloys

- Lattice Structures and their Applications

- Essential Design Rules for Mass 3D Printing

Customized end of arm tooling made with SLS 3D printing

Subscribe to our newsletter to learn more about additive manufacturing.