Projects

Glacier

We make data visible!

In this project, we conducted simulations to model the growth and retreat of a glacier lake along with its glacier. These simulations relied on historical elevation and climate data spanning several decades. Using our model, we forecasted the future of the glacier lake and its surrounding terrain, and subsequently generated an updated elevation map based on these projections. To effectively represent the elevation data, we produced tangible models of the region of interest at various time points, illustrating both past changes and the anticipated future developments. For the creation of the models we programmed dedicated software which allowed us to create printable models to better visualize the data.

Manometer

We make it in one piece!

This manometer serves as a remarkable showcase of the possible achievements through additive manufacturing and compliant mechanisms. By utilizing the pressure within the manometer, an external magnet undergoes a radial movement, consequently altering the magnetic field direction detected by the Hall sensor. This alteration is directly proportional to the pressure within the manometer. Notably, the manometer is a single-piece 3D print, completely devoid of any support structures. Its movement is entirely reliant on compliance, optimized through ingenious engineering. This design approach ensures that even though the part is printed using stainless steel, a notably rigid material, it still exhibits a considerable degree of compliance, even under low-pressure conditions.

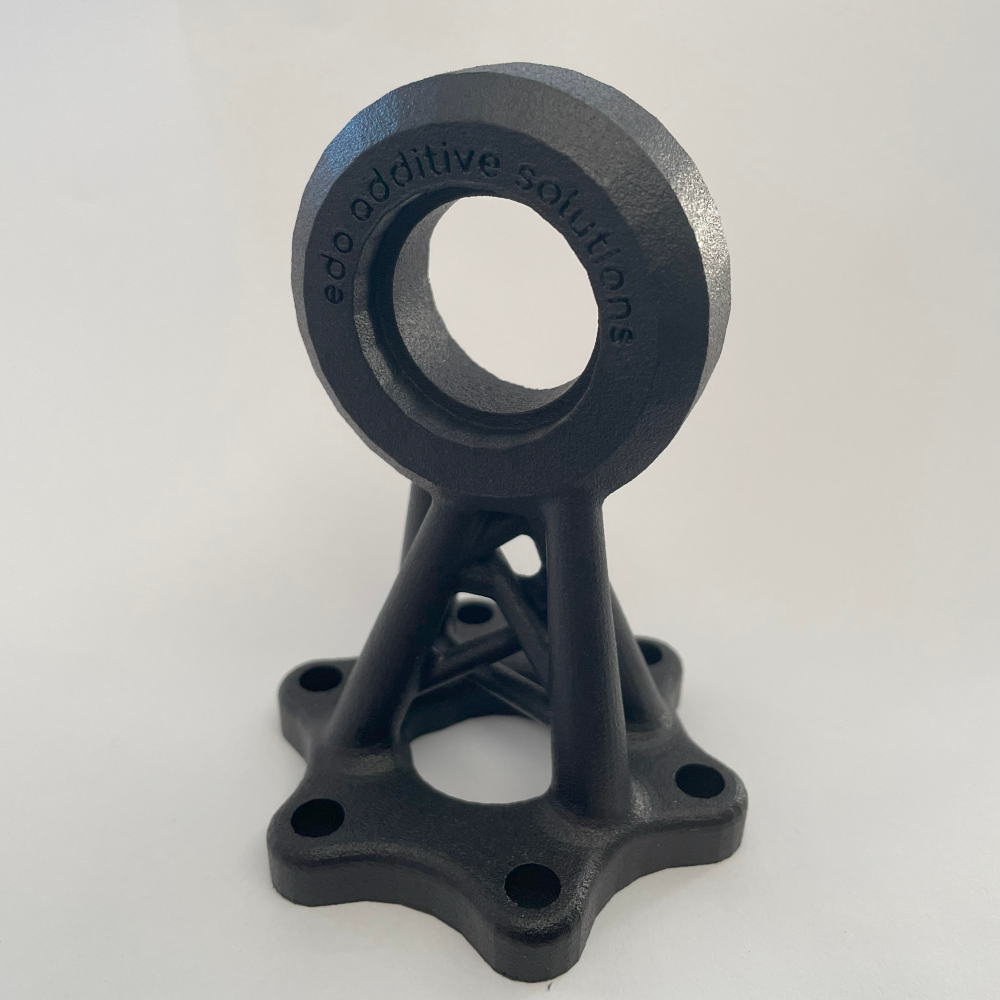

Bracket

We make it lighter, cheaper, smaller, bigger, ... !

Robot arms are versatile tools used in various production applications. However, many of these applications necessitate tool-holding solutions to facilitate the robot’s tasks. Due to the diverse nature of these tasks, universal solutions are limited, making customized brackets the preferred choice. Optimizing weight is crucial for cost-effective usage since a lighter tool head allows for quicker movement and the utilization of smaller, more affordable robot arms. The bracket must still withstand design loads, making the strategic removal of material from specific areas essential. We chose the Selective Laser Sintering (SLS) process because it allowed us to create the exact shape needed without requiring additional supports. The use of engineering-grade polymers further ensures lightweight construction and rapid production turnaround times.

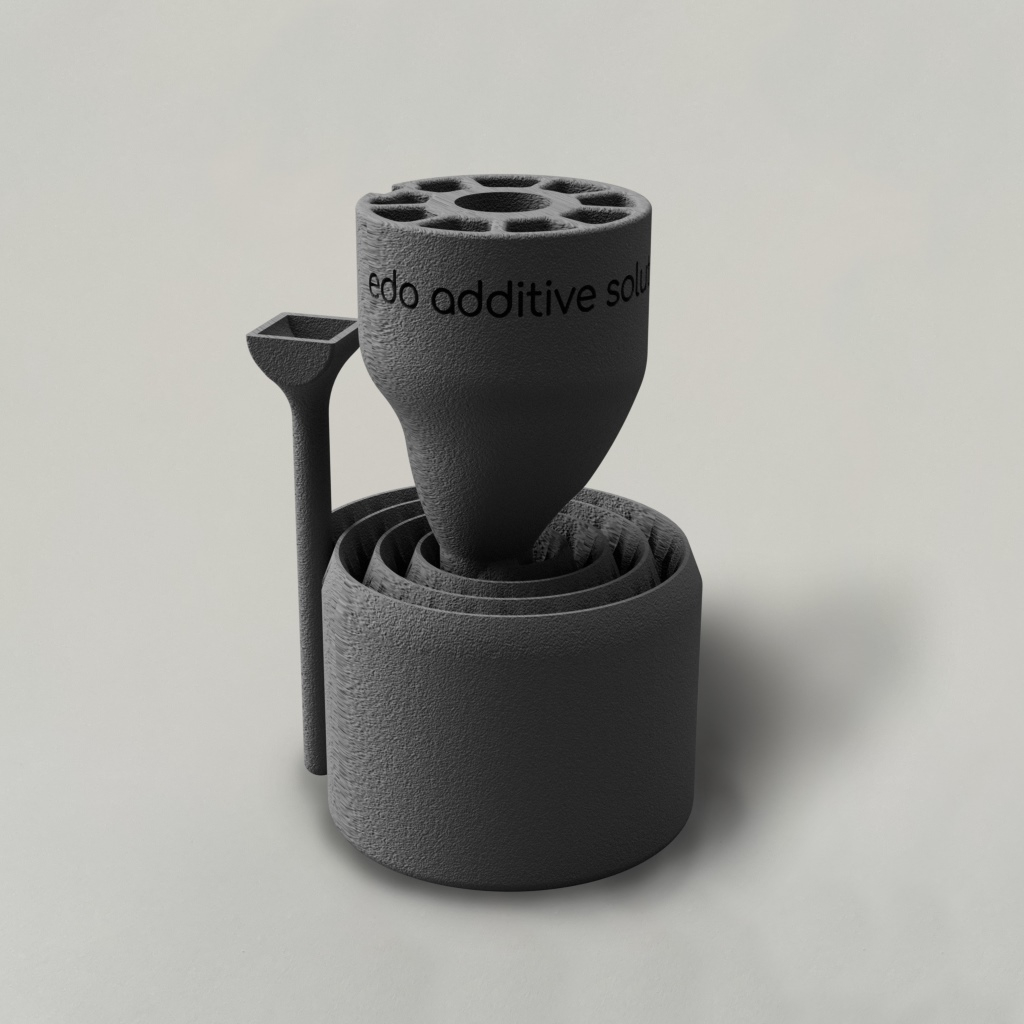

Print in Place Lock

We make assemblies in a single 3D printed part!

3D printing allows us to integrate multiple functions into a single part, print entire assemblies, reduce assembly costs, eliminate errors, and ensure more reliable products. It also offers cost-effective solutions for producing test parts and small batches while enabling complex designs without expensive tooling.

Our expertise in 3D printing empowers us to provide you with solutions tailored to your specific needs. We are here to help you to unlock the full potential of this cutting-edge technology as we designed the lock.