Holistic Benefits of 3D Printed Parts

Introduction

If you think about the benefits of 3D printing, most think of the design freedom and how easy it is to manufacture parts, which could reduce the direct manufacturing costs. But 3D printing has many more benefits besides having more design freedom. In a more holistic view, many 3D printed parts only become economical if you not only consider the direct costs of a part. In this article, we will give a broader overview of the wide-ranging benefits of 3D-printed parts.

Benefits of 3D printing over the product life

One of the big benefits of additive manufacturing is that it keeps the flexibility to make cost reductions in later stages of the product life cycle high. There is no big upfront investment needed in tooling. Other process parameters of the additive manufacturing process stay the same even on larger changes to the printed part. This stands in broad contrast to traditional manufacturing, where changing some details on a part can lead to large changes which locks in the cost of the product very early on.

Another benefit of 3d printing is that designs in the conception and development phase can be validated and tested more quickly, and therefore, inefficient designs have a lower chance to get introduced to the market. There is just a higher number of competing designs that can be tested at the same time and the same development cost.

Holistic Benefits

Most of the time, 3D-printed parts replace one or multiple otherwise traditionally manufactured parts. Quite often, the 3D printed part in itself is not cheaper than the traditional part(s), but it’s still worth it. This is because the 3D printed part has some indirect benefits that by far exceed the possible direct manufacturing costs.

These usually include:

- Less maintenance

- Weight Savings (1 kg can save $2000/year in fuel in commercial aeroplanes)

- Energy savings

- Increased Performance

- Better lead times

Indirect cost savings

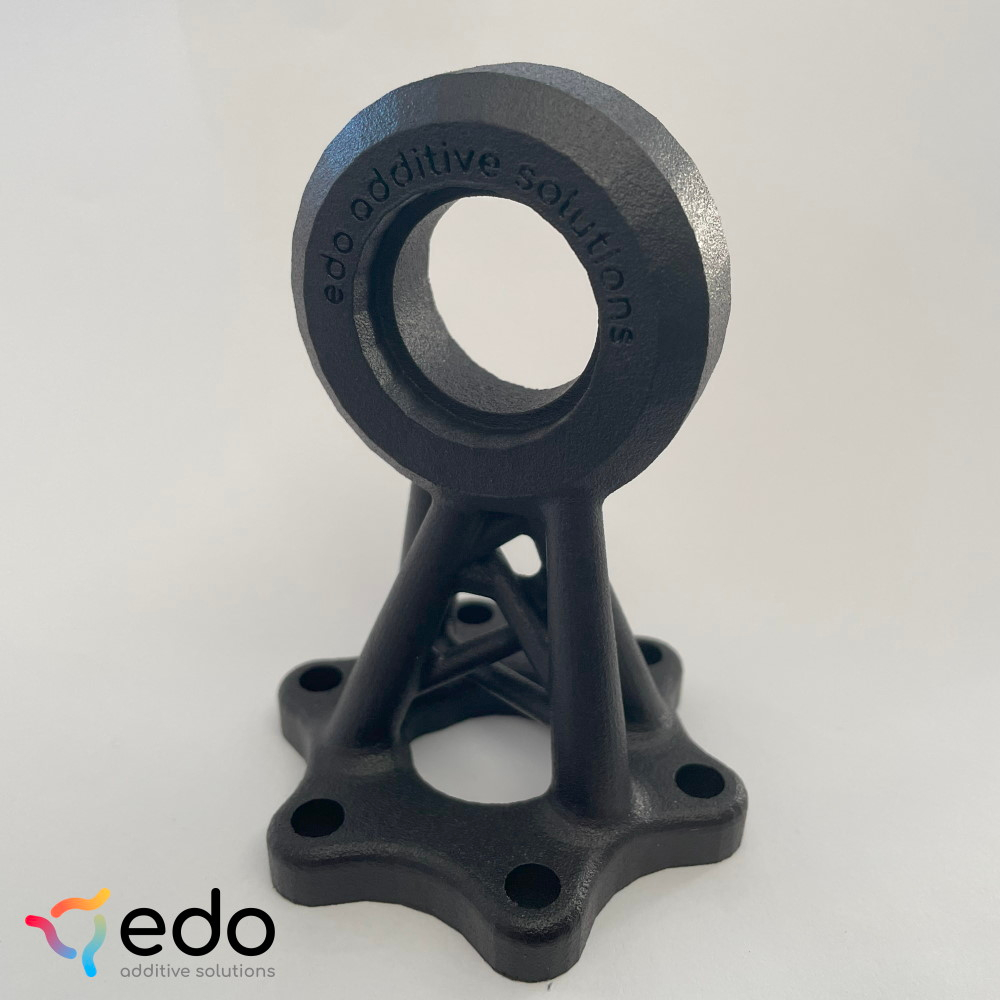

Sometimes, 3D printing is really about cost savings, but by making the 3D printing part extremely cheap, This robot bracket was designed for us to mount a tool to a robotic arm. Of course, you could mill a part to fulfil a similar purpose. However, by using 3D printing, we could reduce the weight quite a lot. That enabled our customers to buy a smaller robotic arm, which saved more money than the cost of the design and 3D printing together.

Customized End of Arm Tooling made with SLS 3D Printing

Economic and ecological impacts during product usage

3D printing usually shows the largest benefits in the increased fit and efficiency during the use of the product. Since 3D printing can easily accommodate personal use, it is possible to design and manufacture the perfect fitting parts for the specific need. This can lead to reduced wear, higher performance and fewer replacements. All these are key aspects to reduce not only the cost over a lifetime (which often are also in indirect nature like reduced fuel/ electricity consumption and reduced maintenance) but also bring huge environmental impacts because reduced energy needs and less trash are beneficial to a greener economy.

Additionally, typical holistic benefits that might not be obvious at first glance are

- Customisation and Personalisation

- Reduction in labour cost because of in-print assemblies and automatisation

- Rapid prototyping, and therefore reduced cost and time in development, which usually leads to better products

- Easy to make changes in later stages of production because of the lack of tooling

- On-demand / On-location manufacturing is feasible with 3D printing

- Supply chain flexibility

- Under the right circumstances, Additive manufacturing can lead to smaller ecological footprints. This is especially true when shipping distances and unused storage parts can be minimised. The part is more efficient and, therefore leads to smaller emissions during the lifetime.

Summary

Often the benefits of 3D printed parts are not obvious at first glance. They can exceed the simple direct manufacturing costs by far by increasing performance, service life or saving cost elsewhere in the process chain.

We are experts in identifying where to use and how to enhance 3D printing in your company. We are here to support you with all these questions about additive manufacturing. Just give us a call or write us here.

The next releases of our newsletter will cover:

- Low Quantity Parts / Replacement Parts with 3D Printing

- 3D Printed Waveguides

- Replacing Moulded Parts with 3D Printed Parts

- How to Minimise the Cost of 3D Prints

- The Truth about Waste in 3D Printing

Subscribe to our newsletter to learn more about additive manufacturing.